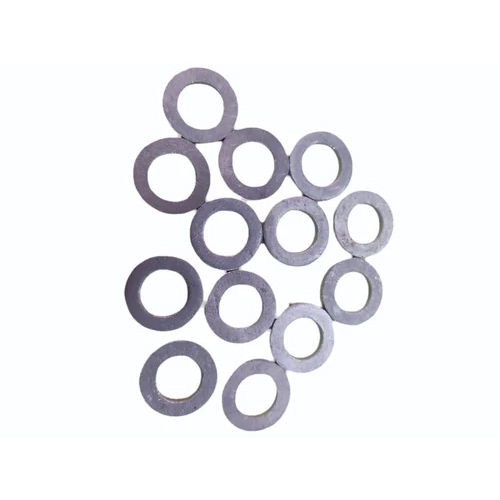

Lead Gaskets

Lead Gaskets Specification

- Usage

- INDUSTRIAL

- Material

- LEAD

- Shape

- ROUND

- Size

- DIAMETER

- Height

- 3 Millimeter (mm)

- Thickness

- 3 Millimeter (mm)

- Surface Treatment

- BLANKING / PUNCHING

- Weight

- 10 Grams (g)

- Color

- SILVER

- Length

- 24 Millimeter (mm)

- Width

- 14 Millimeter (mm)

- Application

- INDUSTRIAL

Lead Gaskets Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 300000 Pieces Per Month

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Domestic Market

- All India

About Lead Gaskets

WE HAVE A WIDE RANGE OF LEAD WASHER USED IN CHOLRINE TONNERS AND IN INDUSTRIAL AREA. WE MANUFACTURE WASHER IN ALL SHAPES AND IN ALL SIZES.

Lead Gaskets Product Specifications

- ROUND

- 14 Millimeter (mm)

- INDUSTRIAL

- SILVER

- LEAD

- 3 Millimeter (mm)

- INDUSTRIAL

- 10 Grams (g)

- DIAMETER

- 24 Millimeter (mm)

- 3 Millimeter (mm)

- BLANKING / PUNCHING

Distinctive Sealing Solutions

These industrial-grade lead gaskets are designed to deliver reliable and durable seal performance in high-pressure operational settings. Thanks to their precisely engineered size and round shape, they offer exceptional sealing integrity, especially in environments requiring resistance to extreme temperatures and corrosive substances.

Expertly Crafted for Industrial Use

The gaskets undergo rigorous blanking and punching processes to achieve smooth edges and consistent thickness. This meticulous craftsmanship guarantees an accurate, leak-proof fit, minimizing the risk of downtime and enhancing the overall efficiency of industrial systems where dependable sealing is critical.

FAQ's of Lead Gaskets:

Q: How are lead gaskets manufactured for industrial applications?

A: Lead gaskets are produced using advanced blanking and punching techniques, which ensure precise dimensions and optimal sealing quality. This process provides smooth edges and a uniform surface, making them suitable for high-performance industrial use.Q: What advantages do lead gaskets offer in industrial environments?

A: Lead gaskets provide excellent corrosion resistance, high malleability for a perfect seal, and durability under pressure. Their properties make them suitable for applications requiring robust and long-lasting sealing in harsh industrial settings.Q: When should lead gaskets be replaced in industrial machinery?

A: Lead gaskets should be inspected regularly and replaced whenever signs of deformation, corrosion, or leakage appear. Frequent maintenance ensures continued safety and operational efficiency in critical industrial equipment.Q: Where are these round lead gaskets commonly used?

A: These gaskets are primarily utilized in a variety of industrial sectors across India, such as chemical processing, manufacturing plants, and equipment requiring strong, metallic seals to prevent leaks and withstand extreme conditions.Q: What is the process for selecting the right lead gasket size and thickness?

A: Choosing the correct lead gasket involves matching its diameter, width, thickness, and height to the equipment's specifications. It's essential to consult with a supplier or technical expert to ensure compatibility with your industrial application.Q: How do blanking and punching surface treatments benefit the gasket's performance?

A: Blanking and punching result in clean, accurate shapes with consistent dimensions, which enhance the gasket's ability to create a tight seal and reduce the risk of leaks. This ensures longer service life and dependable performance.Q: What are the main benefits of sourcing lead gaskets from suppliers, traders, or wholesalers in India?

A: Purchasing from reputable Indian suppliers ensures product authenticity, adherence to industrial quality standards, and competitive pricing. Additionally, local sourcing often leads to better support and faster delivery.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Lead Washer Category

Lead Washer For Chlorine Cylinder

Price 10 INR / Piece

Minimum Order Quantity : 50 Pieces

Usage : Industrial

Size : 24 MM

Surface Treatment : Chrome Finish

Color : Grey

Round Lead Washer

Price 10 INR / Piece

Minimum Order Quantity : 50 Pieces

Usage : Industrial

Size : 20 MM

Surface Treatment : Chrome Finish

Color : Silver

Send Inquiry

Send Inquiry Send SMS

Send SMS